|

Wechat +86-18972582893 |

WhatsApp +86-18972582893 |

Telescopic crawler cranes

The telescopic crawler crane is a new type of crane that combines the flexibility of a truck crane with the powerful lifting capacity of a crawler crane. It is a highly efficient and versatile lifting device that perfectly meets the demands for rapid relocation and efficient operation in complex construction site environments.

The telescopic Crawler Crane Load Moment Indicator (LMI) enhances crane operation safety by continuously monitoring load weight, boom angle, and other parameters to calculate the load moment in real time. If the load moment approaches or exceeds safety limits, the LMI provides visual and audible alerts to operators, enabling them to take corrective actions to prevent overloading, tipping, accidents, and equipment damage.

- Internal storage of crane load charts with real-time display of rated load capacities

- Continuous monitoring and display of load weight, working radius, boom angle, hook position, and other data/status for crane safety assessment and visualization.

- Calculates the load moment in real time. If the load moment approaches or exceeds safety limits, the LMI provides visual and audible alerts to the operator and outputs a stop signal.

-The system allows setting safety limit values and configuring contact buttons, which are password-protected.

- Utilizes automatic sensor compensation algorithms to ensure long-term system accuracy.

- Includes black box functionality for historical data logging, with real-time viewing capabilities.

- Selected monitors and main controllers support USB historical data downloads.

- Supports integration and the expansion of additional features.

- Offers multiple monitor (display) options; select monitors integrate main controller functions to reduce system components and facilitate rapid installation.

Operating Voltage:DC24V

Operating Temperature:- 20 oC ~ + 60 oC

Power dissipation:<20W

Comprehensive error:<5%

Resolving Ability:0.1t

Alarm Volume: >60db

- Provides clear and concise English technical manuals for the quick installation and calibration of LMI systems.

- Factory-stored load charts are available, eliminating the need for customer modifications.

- Reliable, high-quality service with 24/7 engineer support available via email or WhatsApp.

- OEM/ODM solutions with customization options tailored to meet customer requirements.

|

COMPONENTS |

|

||||||||||||

| DISPLAY |

|

||||||||||||

|

PRESSURE TRANSDUCERS |

|

||||||||||||

|

LENGTH/ANGLE SENSOR |

|

||||||||||||

|

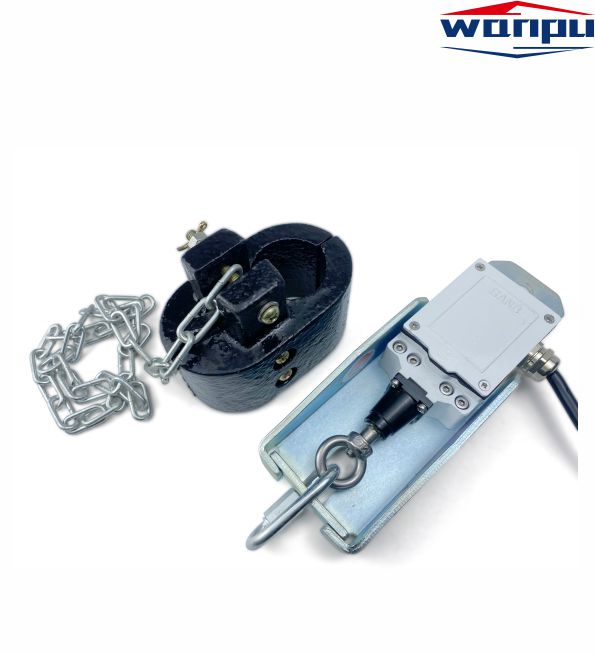

ANTI TWO-BLOCK SWITCH |

|

||||||||||||

|

WARNING LIGHT |

|

-High-quality components are carefully selected to ensure optimal product performance and stability.

-Every product undergoes rigorous inspection and testing before shipment to ensure quality.

-One-year free repair warranty with lifetime complimentary online after-sales support.

-We guarantee 10 years of production continuity for all product components.

- We will respond to every email or WhatsApp message within 24 hours, usually sooner.

- Barring unforeseeable circumstances, we will promptly restore your device to normal operation.

- Experienced engineers are always available to assist you.

You can contact us by email about your order details, or place order on line

E-mail: sales@ycwpkj.com

English User Manual(include all the details of each item) will be offered for installation and trouble shooting. Also free Remote Instant Technical assistance would be offered by ourengineers. Or we can send our engineers to assist you locally

Wooden case or carton, shipping method as customer's request or our suggestion.

How to Select the Right load moment indicator (Load Moment Limiter) for Crawler Telescopic Boom Cranes

The lifting structure components of crawler telescopic boom cranes and mobile cranes are fundamentally similar. When selecting load moment indicator, attention should be paid to the two critical sensors in the load moment limiter: the length sensor and the load sensor.

As a vital component of the load moment indicator, the length sensor must be appropriately selected. Choose a sensor based on the boom length specified in the crane's load chart. For example, if your maximum boom length is 30 meters, we recommend selecting a length sensor with an effective detection range of 40 meters.

The load sensor, another vital component, typically uses a hydraulic sensor by default. This measures the pressure in the hydraulic cylinder and calculates the actual load and moment through appropriate algorithms. We also offer a pulley-type load sensor mounted at the boom tip. The hoisting wire rope passes through three pulleys, enabling direct detection of the force on the wire rope. The key difference between these load sensors is that hydraulic sensors are compact and lightweight but require longer calibration times. Pulley-type load sensors are heavier but offer shorter calibration times. Selection depends on specific requirements.Should you encounter any issues when selecting a load/moment limiter for mobile cranes, please feel free to contact us at any time. We provide complimentary technical support and solution recommendations.

Contact: Lu

Phone: +86-18972582893

Tel: +86-0717-6746086

Email: sales@ycwpkj.com

Add: No.33 Dalian Rd,Yichang, Free Trade Zone(Hubei) China